So I met with my clients and we all agreed that it would be best to wait until I've got my hollows and rounds finished so that an accurate reproduction can be made. Until I finish the four or so planes I need to make this moulding, consider me a full part-time planemaker.

Layout phase for the roughed out blanks, in this case done while watching Law and Order (favorite all time cop show). Bed, breast, mouth, mortice, sole width and wedge lead are drawn on in all necessary places.

Two pitch boards for layout of plane length, pitch and in some cases escapement. There's also a wedge template, used for checking an in-progress mortice as well as laying out finials. I use one Tablesaw/shooting jig to cut all wedges so there is never variation.

On SMC I posted a little writeup on the remanufacture of this once warped and ironless Summers Varvill #6 Round into a #6 hollow for my quarter set.

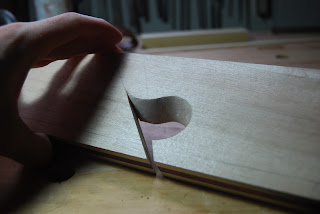

Blind side.

Sole

This is my layout block for sawing bed and breast angles, I hate it, works fine, but I've realised that Larry Williams' has a strip attached to the bottom overhanging both sides, so it can be flipped to any orientation for sawing. I need to rip it off and attach a steel or brass sole to it.

Time to get off my ass and get back to work. I have a lot of mouths to feed.